Understanding PolyJet Technology: Revolutionizing 3D Printing

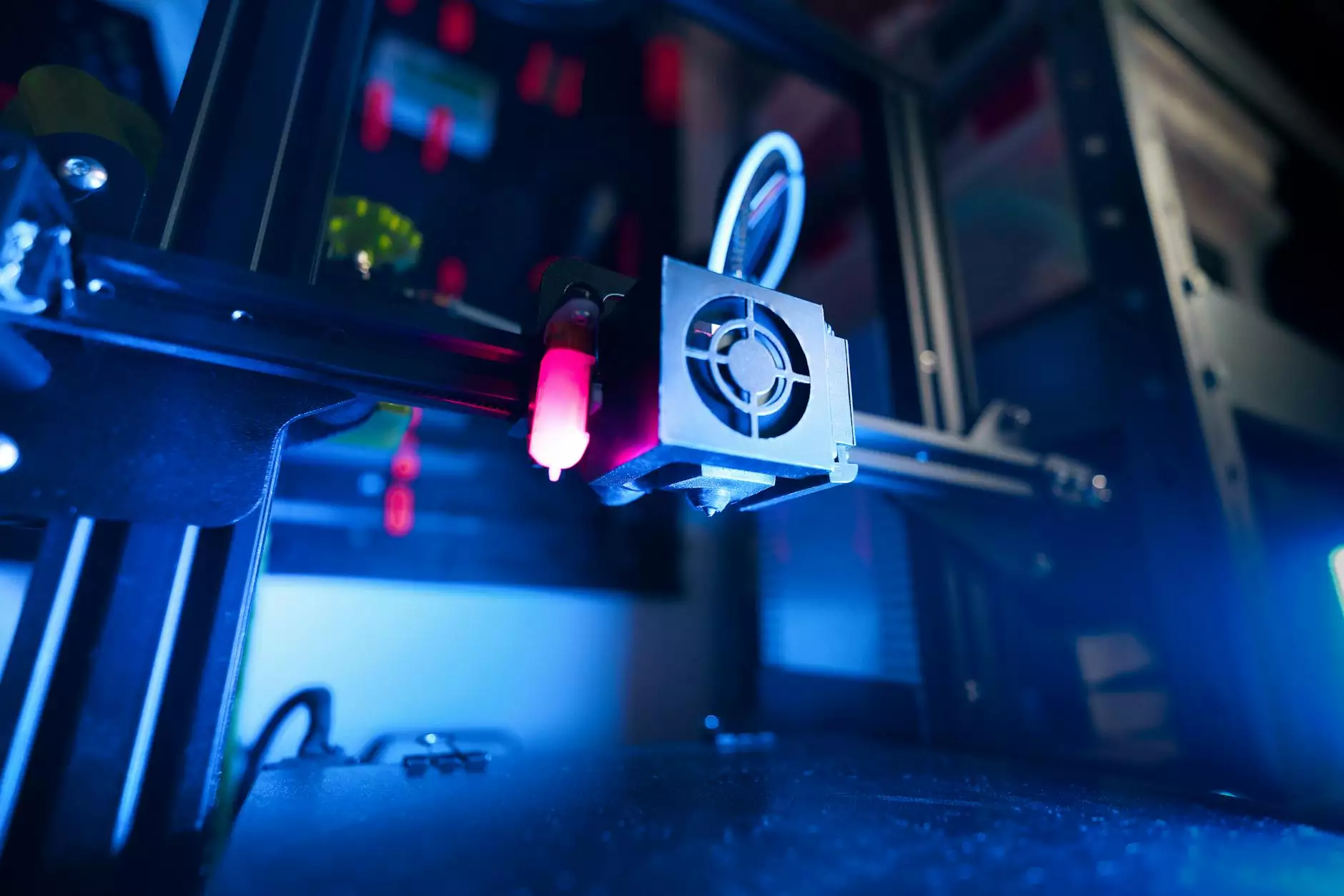

PolyJet technology stands at the forefront of the 3D printing revolution, providing businesses with cutting-edge solutions for manufacturing, product design, and creative applications in the art supplies industry. This intricate method allows for the simultaneous deposition of multiple materials and colors, resulting in strikingly realistic prototypes and end-use products.

The Basics of PolyJet Technology

PolyJet technology operates by spraying tiny droplets of liquid photopolymer onto a build platform, which are then cured by UV light to create solid layers. This process enables the rapid production of complex geometries with high precision.

Key Features of PolyJet Technology

- Multi-material Printing: Combine different materials in a single print to create complex products with varied properties.

- High Resolution: Achieve layer thickness as fine as 16 microns, resulting in smooth surfaces and fine details.

- Color Printing: Integrate multiple colors seamlessly for enhanced aesthetic appeal.

- Versatility: Ideal for creating anything from prototypes to intricate art pieces.

Applications of PolyJet Technology in Various Industries

The versatility of PolyJet technology has led to its adoption across a wide array of industries, including:

1. Product Design and Development

In the realm of product design, speed and quality are paramount. PolyJet's ability to produce highly detailed prototypes allows designers to test form, fit, and function efficiently. Businesses can:

- Conduct thorough usability tests before finalizing designs.

- Quickly iterate on designs based on feedback.

- Present realistic prototypes to stakeholders, enhancing decision-making.

2. Art and Craft Supplies

For artists and crafters, PolyJet technology opens doors to unprecedented creative possibilities. Art supplies manufacturers can take advantage of:

- Producing intricate sculptural elements with fine details.

- Creating custom tools that meet specific artistic needs.

- Experimentation with color and material combinations that inspire new art forms.

3. Medical Industry

The medical sector benefits immensely from PolyJet technology, particularly in creating realistic anatomical models for surgical planning and education. This includes:

- Custom dental and orthopedic models tailored to individual patients.

- Facilitating better surgical outcomes through practice on 3D printed models.

- Developing medical devices with precise specifications.

Why Choose PolyJet Technology?

Choosing PolyJet technology means embracing innovation and efficiency. Here are some compelling reasons:

Cost Efficiency

While high-quality manufacturing often comes at a premium, PolyJet technology minimizes costs by reducing material waste and shortening production times. Businesses can:

- Reduce the need for costly tooling.

- Lower material costs by optimizing the use of various resins.

- Enhance overall productivity through rapid iteration.

Customization and Personalization

In an age where consumer preferences evolve rapidly, the ability to customize products is invaluable. PolyJet printing allows businesses to:

- Create bespoke items tailored to customer specifications.

- Offer personalized designs that resonate with individual consumers.

- Rapidly produce limited runs of custom products, enhancing market flexibility.

Challenges and Considerations

Despite its many advantages, PolyJet technology isn't without its challenges. Businesses must consider:

- Material Limitations: While diverse, not all materials are suitable for all applications.

- Post-Processing Needs: Finished products may require additional finishing steps.

- Initial Investment: The cost of acquiring PolyJet printers and materials can be significant.

The Future of PolyJet Technology

The potential for PolyJet technology continues to expand as researchers innovate and refine the process. Applications are broadening into sectors like aerospace, automotive, and even fashion, where bespoke and complex components are needed.

Emerging Trends

- Sustainability: Efforts are underway to develop eco-friendly materials that minimize environmental impacts.

- Smart Materials: The integration of materials that respond to environmental stimuli is becoming more prevalent.

- Integration with Advanced Technologies: Combining PolyJet printing with AI and machine learning for predictive design analytics.

Conclusion: Embracing Innovation with PolyJet

As businesses in various sectors strive for competitive advantages, adopting PolyJet technology can be a game changer. By offering unmatched versatility, precision, and the ability to innovate rapidly, PolyJet stands ready to enhance production processes and creativity.

Incorporating this transformative technology into your operations not only enhances product offerings but also aligns your brand with the future of manufacturing. Whether you're in product design, art supplies, or any other industry, the time to embrace the power of PolyJet technology is now.